Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Machine Learning-Based Demand and Pricing Optimization for a Resilient Automotive Supply Chain

Authors: Shubhangi Ambekar, Vedant Dore, Harshwardhan Garad, Krishna Bhite, Manisha Mali

DOI Link: https://doi.org/10.22214/ijraset.2024.64904

Certificate: View Certificate

Abstract

In the supply chain management of the automotive industry, this paper investigates the use of demand forecasting, supply optimization, and price optimization. Optimizing the supply chain is essential for satisfying changing customer needs, cutting expenses, and increasing revenue. This study aims to improve the accuracy of demand prediction, optimize supplier relationships, and simplify pricing strategies through the use of ML-driven models. To solve the difficulties faced by automakers in a volatile market, the suggested framework combines historical data analysis, market trends, and inventory management strategies. The results help the automotive industry\'s supply chain systems become more flexible and resilient.

Introduction

I. INTRODUCTION

In the dynamic automotive industry, customer needs and competitiveness in this business are achieved based on effective supply chain management. The automobile manufacturers are involved in complex networks which include distributors, logistics firms, and suppliers who come together to deliver automobiles and parts all over the globe. That is why this degree of interconnectivity that exists in the automotive supply chain makes it prone to several disturbances caused by economic, geopolitical, and global pandemics. This calls for flexible, responsive, and resilient solutions that can accommodate variations in demand, nonstationary market conditions, and dynamic pricing mechanisms.

Innovative ways through which the supply chain operations of automakers can adapt to these challenges can be drawn from artificial intelligence and machine learning. Through real-time data and historical data, automakers can power data-intensive decisions and make improvements in many aspects of the supply chain, all through advanced algorithms. Two methods used in this research article are Linear Regression and XGBoost; these two target the two primary automotive supply chains: pricing optimization and demand forecasting.

Accurate demand forecasting is of prime importance to avoid risks of overstock and stockouts and to align the production cycle with market demand. Among the basic statistical methods, linear regression simulates the relationship between dependent and independent variables, giving insights into trends of demand. However, in a large dataset where intricate, non-linear interactions can be managed, there is XGBoost - well known for its effectiveness and efficacy in predictive analytics. Together, these algorithms help auto manufacturers take decisions in the right direction, and the correct predictions regarding shifting demand patterns will be made.

Another relevant area in which AI-enabled insights can bring immense value is in pricing optimization. It requires the need for an appropriate pricing strategy without compromising on market competitiveness between profitability and customer satisfaction. Linear regression is applied over historical data of pricing trends to discern patterns and dependencies influencing optimal pricing strategy. Advanced predictive capabilities of XGBoost enable the design of dynamic pricing models that can respond to real-time market conditions. This strategy improves customer experience and competitive positioning by boosting revenue growth and aligning prices with demand trends.

The current research study proposes an exhaustive framework, which integrates Linear Regression with XGBoost. It suggests ways in which, in the context of present issues in automotive supply chain management, algorithms like this can be used to enhance the accuracy of demand forecasts and fine-tune pricing strategies. Such research adds valuable insights to data-driven supply chain optimization in developing more resilient, agile, and efficient automotive supply chains using AI and ML in transforming it.

II. LITERATURE REVIEW

- This paper [1] introduced a flexible supply chain model for the automotive industry that adapts to changing customer demands. By using advanced technology for data sharing, a forecast-driven production system, and closer collaboration with suppliers, the model helps manufacturers stay competitive and responsive to market shifts.

- In this study [10], the authors proposed a strategy for managing supply chains in large multinational companies. They focused on streamlining inventory and freight plans, using real-time data for cost management, and creating global supplier agreements. The idea was to make SCM a key player by aligning it directly with the CEO’s strategic vision.

- This paper [4] took a deep dive into the history of supply chain management and mapped out how it’s evolved over time. By comparing SCM with related fields like logistics and operations management, the authors offered a clearer understanding of how it stands out and where it’s heading.

- This study [11] looked at 30 articles from 2007 to 2018, analyzing key trends in industrial engineering research related to the automotive supply chain. It focused on performance measurement, drawing insights from the works of 80 authors from 12 different countries.

- In this research [6], the authors tested five machine learning algorithms to predict demand in supply chains. They found that Extreme Learning Machine (ELM) outperformed other methods, including K-nearest neighbors and decision trees, in terms of accuracy and efficiency.

- This paper [2] explored how AI and machine learning are transforming supply chain operations. The review highlighted the many ways these technologies improve decision-making, resource management, and sustainability efforts across the supply chain.

- In another 2023 study [3], researchers explored the role of AI in supply chain management, focusing on techniques like neural networks, fuzzy logic, and genetic algorithms. They also tackled emerging topics such as sustainability, big data, and automation in SCM.

- A project [8] focused on building a user-friendly platform that helps businesses forecast future product needs. Using Weka software, the system scored highly in usability and functional stability, making it easier for companies to predict demand and manage inventory.

- This study [5] addressed three common supply chain challenges: inventory management, budget forecasting, and supplier analysis. It used time series prediction models like ARIMA, Holt-Winters, and LSTM to provide more accurate forecasts.

- This paper [7] combined advanced machine learning models, LightGBM and PSO-LSTM, to enhance inventory management and demand forecasting. The results showed that optimizing these processes significantly improved a company’s turnover rate and order fulfillment accuracy.

- A 2024 review [9] examined how AI is being integrated into sustainable supply chain management. The study used a topic modeling approach to show that most of the research in this area comes from engineering and business management, highlighting where future research could be focused.

III. METHODOLOGY

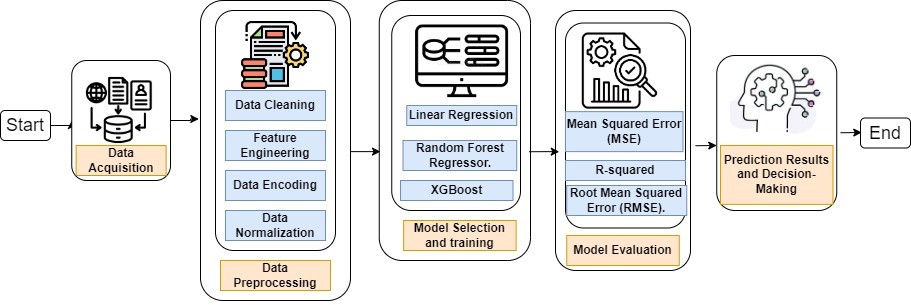

Fig 1: System Workflow Diagram

Using AI and ML, this study provides a structured framework for demand forecasting and pricing strategy in an automotive supply chain. This covers every stage, from situation identification to software and hardware selection, data collection and preprocessing, model construction, and model evaluation with system deployment. The distinct issues posed by a changing automotive supply chain are addressed in each phase.

A. Problem Identification

The automotive supply chain is a vast and interconnected web of operations that includes distributors, retailers, suppliers, and manufacturers. The level of difficulty in effectively managing supply chain activities rises with such complexity. Therefore, in order to tackle these problems, this study uses AI and ML techniques such as XGBoost, Random Forest Regressor, and Linear Regression to enhance the accuracy of demand forecasting and pricing strategy optimization. Therefore, the goal of this research is to create a robust, adaptable framework that can handle changing market demands, improve decision-making skills, and sustain long-term company success in the automotive industry.

B. Software and Library Selection

Python is chosen as the primary programming language because of its robust package of libraries specifically targeted towards activities in data analysis and machine learning. Pandas is used for data manipulation, cleaning and transformations-that generally considered in handling missing values, outlier removals, and data formatting. Operations involving numbers were done using NumPy. A crucial role was played in processing huge amounts of datasets and running numerical transformations. It laid the ground to work on implementing these machine learning models, such as Linear Regression and Random Forest Regressor, using Scikit-learn. In addition, the gradient boosting library XGBoost was used as it supports extreme complexity in handling data, with better performance when dealing with complex datasets. Libraries are thus essential because they allow for the efficient handling and processing of data along with developing and evaluating a model, which is critical in building a scalable and adaptive framework suited to the dynamic requirements of the automotive industry.

C. Hardware Configuration

For AI and ML model training, a high-performance hardware setup was selected to meet the rigorous computing demands. Initial data exploration and testing of smaller models were conducted using a local workstation equipped with an SSD and at least 16GB of RAM. For large-scale model training, high-performance CPU/GPU servers were employed, particularly for computationally demanding tasks like training XGBoost models on enormous datasets. With this setup, the training process is accelerated, and the framework is guaranteed to handle complex models and large data volumes, which are typical in the automotive supply chain.

D. Data Acquisition and Preprocessing

In this study, numerous data sources were leveraged to acquire information, including historical sales records, inventory data, supplier data, and logistical data. To further enhance the analysis, a Kaggle dataset was employed. Economic indicators and other contextual data were added to the model to improve its accuracy. A variety of actions were done in data preprocessing to prepare the data for analysis. These included imputing or eliminating missing variables and locating and resolving outliers to reduce their influence on the models. To improve predictive capability, feature engineering was used to develop extra characteristics, like seasonality indicators. Label encoding was used to encode categorical data, such as automobile models and seasons, and numerical features were standardized to guarantee interoperability among the chosen models. This comprehensive data preparation ensured that the data was uniform, clean, and ready for model training.

E. Model Selection and Training

Three machine learning models—Linear Regression, Random Forest Regressor, and XGBoost—are used by the framework. Each link in the automobile supply chain has these models installed. The model uses Linear Regression for the first stage of demand forecasting because it is an interpretable model that can help explain the relationship between demand and other independent variables. However, because more non-linear patterns are more complex, Random Forest Regressor and XGBoost are also used. While XGBoost is a sophisticated gradient boosting technique that increases forecast accuracy by modeling complex relationships in the data, Random Forest Regressor, an ensemble learning approach, is ideal for feature interaction.

Finally, each model's hyperparameters were adjusted to maximize performance, and K-fold cross-validation was used to make sure the models were generalizable across various datasets. An integrated approach to managing pricing strategies, supplier optimization, and demand forecasting in the automotive supply chain is made possible by this set of models.

F. Algorithm Selection and Implementation

The study uses a set of machine learning algorithms designed to optimize pricing strategies and demand forecasting, among other areas of the automotive supply chain. Every algorithm is chosen according to its capacity to manage particular jobs, the properties of the data, and the level of complexity required. The following algorithms are used:

Linear Regression is a foundational statistical technique commonly used for predicting numerical outcomes. It analyses the relationship between one or more independent variables and a dependent variable by fitting a linear equation to the observed data. In our study, we employed Linear Regression as a baseline model for demand forecasting. This approach allows us to gain initial insights into the factors that influence demand within the automotive supply chain, making it a straightforward yet effective starting point for our analysis.

Random Forest Regressor is an ensemble learning method that enhances prediction accuracy by combining multiple decision trees. During training, each tree is constructed from a random subset of the data, and their collective output is averaged to produce the final prediction. This technique effectively captures complex relationships and interactions among features while minimizing the risk of overfitting. In our research, we utilized the Random Forest Regressor to improve the precision of demand forecasts, leveraging its ability to handle diverse data patterns inherent in the automotive sector.

XGBoost (Extreme Gradient Boosting) is a highly efficient implementation of gradient boosting that focuses on speed and performance. It uses decision trees as base learners and incorporates advanced regularization techniques to prevent overfitting. The algorithm's ability to process large datasets quickly and model complex relationships makes it particularly valuable in our analysis. In this study, we integrated XGBoost to enhance our demand forecasting capabilities, allowing for more accurate predictions by effectively addressing non-linear patterns within the data.

Additionally, we explored various machine learning approaches, including Support Vector Machines (SVM) and Gradient Boosting Machines (GBM), to assess their effectiveness in different facets of supply chain management. By incorporating a range of algorithms, our framework aims to provide a comprehensive and adaptable solution for optimizing the automotive supply chain.

IV. RESULTS

A. Demand Forecasting Performance

The outputs of all three techniques, namely, Linear Regression, Random Forest Regressor, and XGBoost, show that there are significant differences as far as the performance of the models is concerned in terms of demand prediction in the context of the chain of supply for the automotive industry. The above performance metrics that include Mean Squared Error (MSE), R-squared, Root Mean Square Error (RMSE), and accuracy were used to assess and evaluate each model.

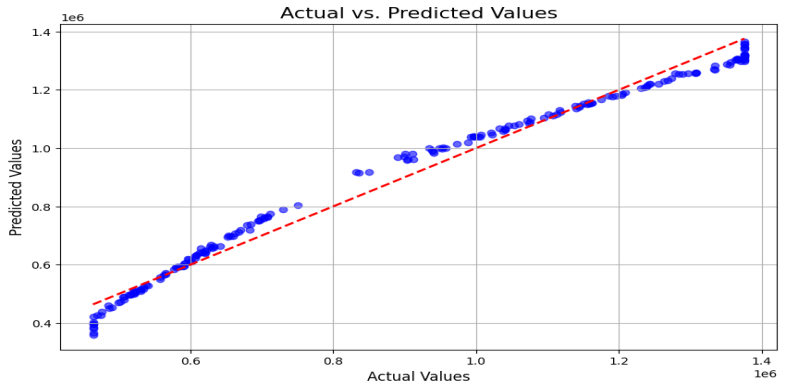

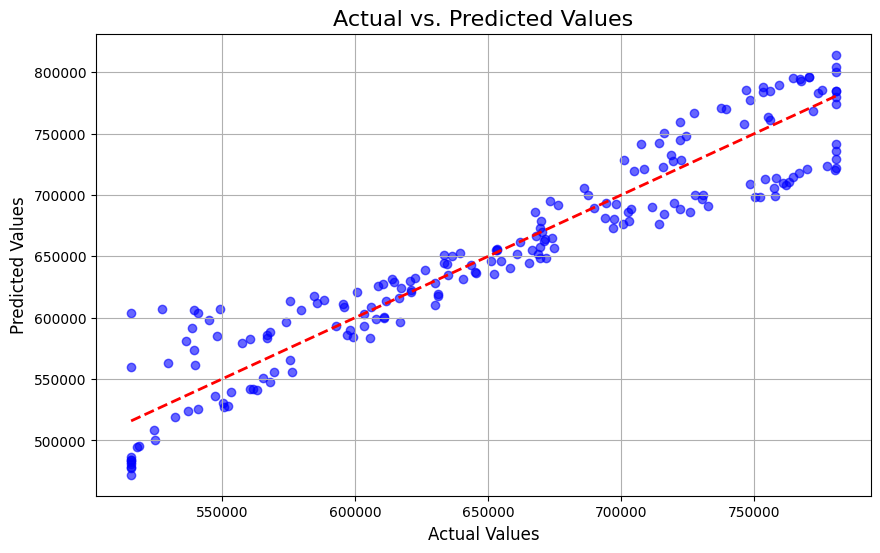

1) Linear Regression: With the Linear Regression model, a good baseline of demand forecasting was realized. On training data, it provided an MSE of 1.5 billion, R² of 0.9838, and an RMSE of 39,817.96, with accuracy reaching 95.52%. Testing data outcomes were similar, with an MSE of 1.70 billion, R² of 0.9829, RMSE of 41,290.17, and accuracy of 95.67%. As shown in Fig 2, the model's predicted values align closely with actual values, demonstrating its effectiveness. Generally, the Random Forest Regressor performed well for trend prediction but struggled with non-linear relationships, occasionally resulting in higher error rates.

Fig 2: Linear Regression For Demand Forecasting

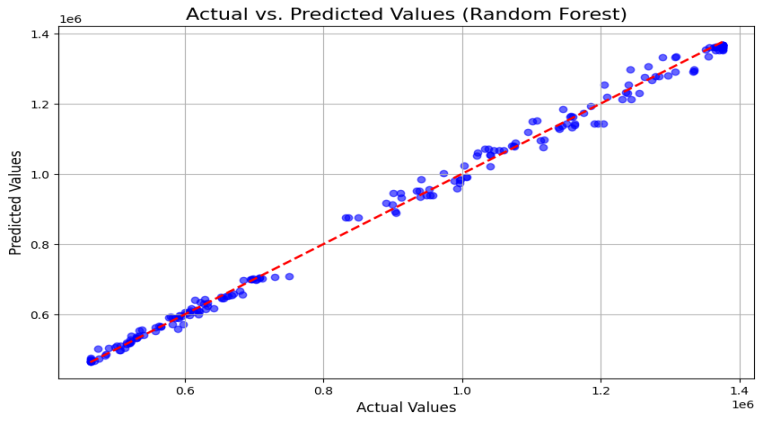

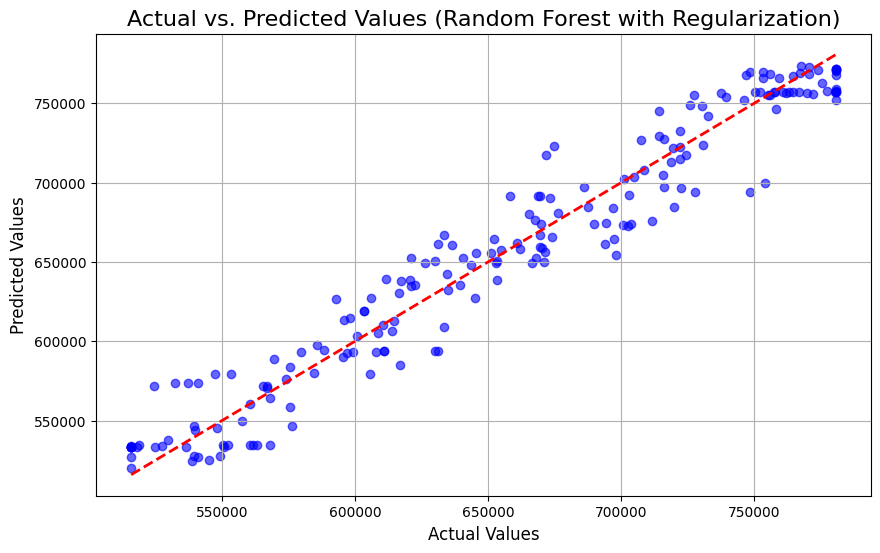

2) Random Forest Regressor: The Random Forest Regressor performed significantly better than the Linear Regression model. On the training data, it achieved an MSE of 233.86 million, R² of 0.9976, and an RMSE of 15,292.36, with an accuracy of 98.71%. Testing results were also robust, with an MSE of 377.48 million, R² of 0.9962, RMSE of 19,428.95, and an accuracy of 98.39%. Cross-validation confirmed these findings, yielding an MSE of 381.51 million. As shown in Fig 3, the Random Forest model captured complex patterns in the data more effectively, making it the best-performing model overall.

Fig 3: Random Forest Regressor For Demand Forecasting

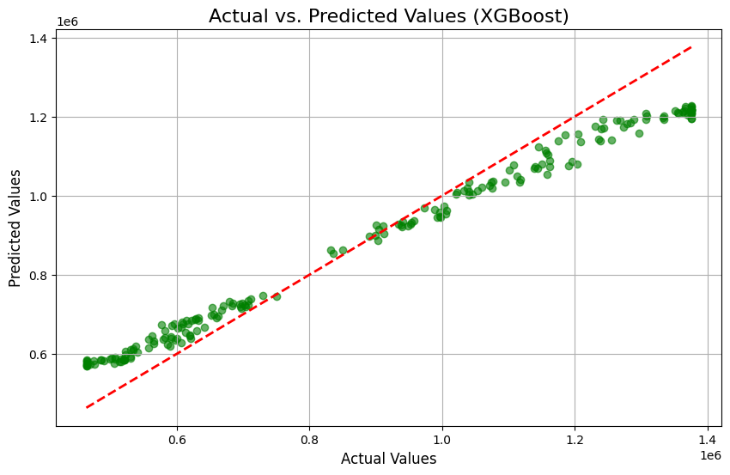

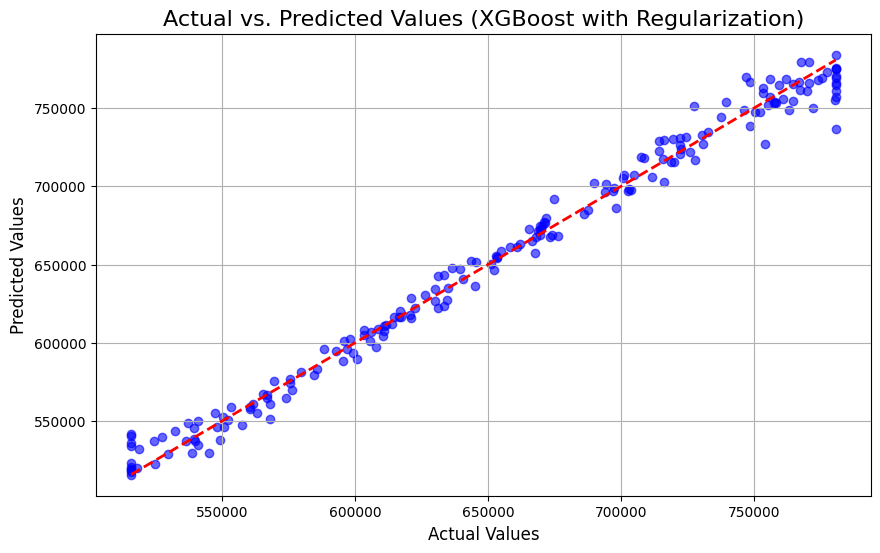

3) XGBoost: The XGBoost model performed worse than the Random Forest model. With respect to the training data, the performance was MSE 5.62 billion, R² of 0.9426, RMSE 74,995.35 with 91.51% accuracy. The testing data followed the same trend: MSE 6.92 billion, R² of 0.9304, RMSE 83,199.85, and an accuracy of 91.45%. Cross-validation had an MSE of 6.74 billion, showing XGBoost really did not apply well to this dataset as compared to the previous models, as shown in fig 4.

Fig 4 : XGBoost For Demand Forecasting

3) Comparative Analysis: The below Table shows, best model for demand forecasting was Random Forest Regressor, always presenting the minimum error rate and the highest accuracy. Linear Regression established a good baseline but waned as more complex and nonlinear patterns came into effect. XGBoost was within acceptable levels but not within the level of Random Forest for this case.

|

|

Linear Regression |

Random Forest Regressor |

XGBoost

|

|

Mean Squared Error (MSE) |

1,704,878,435.79 |

377,483,918.74 |

6,922,214,275.67 |

|

R-squared |

0.9829 |

0.9962 |

0.9304 |

|

accuracy |

95.67% |

98.39% |

91.45% |

|

Root Mean Squared Error (RMSE). |

41,290.17 |

19,428.95 |

83,199.85 |

Fig 5: Table Of Comparison for Demand Forecasting

B. Pricing Optimization Performance

To compare three models—Linear Regression, Random Forest Regressor, and XGBoost for the optimal setting of the pricing strategy—both datasets, namely, the training and testing datasets, were used. The performance metrics applied for comparison are Mean Squared Error (MSE), R-squared (R²), Root Mean Squared Error (RMSE), and accuracy on optimal price points that best predict optimal price points.

1) Linear Regression: Linear Regression provided a good base line with an MSE of 825.73 million on the training data, having an R² of 0.8831, RMSE of 28,735.59 and 96.34% accuracy. Testing data was almost identical with an MSE of 798.62 million, R² of 0.8845, and 96.44% accuracy. The fig 6 shows that , it was good but could not classify complex patterns that have relatively higher error margins in contrast with other models.

Fig 6 : Linear Regression for Price Optimization

2) Random Forest Regressor: The Random Forest Regressor performed better. For the training set, it had a MSE of 317.28 million with an R² of 0.9551 and RMSE of 17,812.32, with an accuracy of 97.87%. On the testing data, it resulted in an MSE of 370.25 million, an R² of 0.9465, and RMSE of 19,241.99, coupled with 97.59% accuracy; it can therefore capture complex relationships and generalize better.

Fig 7: Random Forest Regressor for Price Optimization

3) XGBoost: XGBoost outclassed both models with a training MSE of 41.11 million, R² of 0.9942, RMSE of 6,411.99, and 99.27% accuracy. Testing was similarly robust, with an MSE of 85.81 million, R² of 0.9876, RMSE of 9,263.46, and 98.96% accuracy. Cross-validation did confirm its robustness, thus making it the most accurate model in pricing predictions.

Fig 8: XGBoost for Price Optimization

4) Comparative Analysis: On comparing all three models , below table gives us idea that XGBoost is best-performing model with the highest accuracy and lowest error rates. Random Forest was also doing well; the model that was performing the poorest in this context is Linear Regression, failing to capture the complex dynamics of pricing.

|

|

Linear Regression |

Random Forest Regressor. |

XGboost

|

|

Mean Squared Error (MSE) |

798623327.945 |

370254368.13 |

85811728.90 |

|

R-squared |

0.884 |

0.947 |

0.988 |

|

accuracy |

96.44% |

97.59% |

98.96% |

|

Root Mean Squared Error (RMSE). |

28259.92 |

19241.99 |

9263.47 |

Fig 9: Table Of Comparison for Price Optimization

Conclusion

This research highlights the need for embedding AI and ML in the management of an automotive supply chain, particularly in applications of demand forecasting, supplier optimization, and price determination. By applying Linear Regression, Random Forest Regressor, and XGBoost, we demonstrate that advanced models can make processes more efficient and smarter decision-making. In the case of demand forecasting, Random Forest was the most efficient tool that handled complicated patterns well, while Linear Regression was not able to handle non-linear relationships well. Pricing optimization best is optimized with XGBoost for it has proven to have the highest accuracy and the lowest error rates during optimization of the pricing strategy. Overall, these ML-facilitated models greatly enhance the predictive power and operational performance of a system. The proposed framework empowers automotive supply chains to better respond to market fluctuations hence improving flexibility, resilience, and profitability. This research highlights the transformative impacts of ML in positioning automotive supply chains toward the future.

References

[1] N. M. Ambe and J. A. Badenhorst-Weiss, \"An automotive supply chain model for a demand-driven environment,\" Department of Business Management, University of South Africa (Unisa), South Africa, 2011. [2] G. Elkady and A. H. Sedky, \"Artificial Intelligence and Machine Learning for Supply Chain Resilience,\" Arab Academy for Science, Technology & Maritime Transport, Alexandria, Egypt, and College of Computing, Arab Academy for Science, Technology, and Maritime Transport, Alexandria, Egypt, 2023. [3] B. Ferreira and J. Reis, \"Artificial Intelligence in Supply Chain Management: A Systematic Literature Review and Guidelines for Future Research,\" Lusófona University, 2023. [4] S. Parkhi, S. Joshi, S. Gupta, and M. Sharma, \"A Study of Evolution and Future of Supply Chain Management,\" Symbiosis International University, 2015. [5] A. Limbare and R. Agarwal, \"Demand Forecasting and Budget Planning for Automotive Supply Chain,\" REVA Academy for Corporate Excellence, Bengaluru, India, 2023. [6] M. Zohdi, M. Rafiee, V. Kayvanfar, and A. Salamiraad, \"Demand forecasting based machine learning algorithms on customer information: An applied approach,\" Bharati Vidyapeeth’s Institute of Computer Applications and Management, 2022. [7] W. Tang, \"Improvement of Inventory Management and Demand Forecasting by Big Data Analytics in Supply Chain,\" College of Business Management, Xiamen Huaxia University, Xiamen, Fujian, 361012, China, 2024. [8] A. A. P. Arnaiz, L. S. Cristal, A. O. Fernandez, M. R. F. Gubaton, D. V. Tanael, and C. J. Centeno, \"Optimizing inventory management and demand forecasting system using time series algorithm,\" College of Computer Studies, Global Reciprocal Colleges, Philippines, and Information Technology Department, Faculty of Assistant Professor, Pamantasan ng Lungsod ng Maynila, Philippines, 2023. [9] C. Qu and E. Kim, \"Reviewing the Roles of AI-Integrated Technologies in Sustainable Supply Chain Management: Research Propositions and a Framework for Future Directions,\" Graduate School of Advanced Science and Technology, Japan Advanced Institute of Science and Technology, Nomi 9231292, Japan, and Southampton International College, Dalian Polytechnic University, Dalian 116034, China, 2024. [10] F. J. Ferriols, J. Mula, and M. Díaz-Madroñero, \"Supply Chain Management as the Company Engine in Automotive Manufacturing,\" Department of Business Management and Research Center of Production Management and Engineering (CIGIP), Universitat Politècnica de València, Spain, 2013. [11] R. Lemgharia, D. Sarsria, C. Okar, and A. Es-satty, \"Supply chain performance measurement in the automotive sector: A structured content analysis,\" National School of Applied Sciences of Tangier, Abdelmalek Essaâdi University, Tangier, Morocco, and National School of Applied Sciences of Berrechid, Hassan the 1st University, Settat, Morocco, 2019.

Copyright

Copyright © 2024 Shubhangi Ambekar, Vedant Dore, Harshwardhan Garad, Krishna Bhite, Manisha Mali. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64904

Publish Date : 2024-10-29

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online